In the second of our two-part Q&A series, walking through the start-to-finish process for SkyX’s...

Q&A: Midstream Pipeline Integrity Services – Data Collection

In the first of a two-part Q&A series, walking through the start-to-finish process for SkyX’s midstream pipeline integrity services, we sat down with Josh MacDougall – Flight Operations Manager –to understand how data collection and flight operations play out on a pipeline Right-Of-Way (ROW).

To start, tell us a bit about what you do at SkyX.

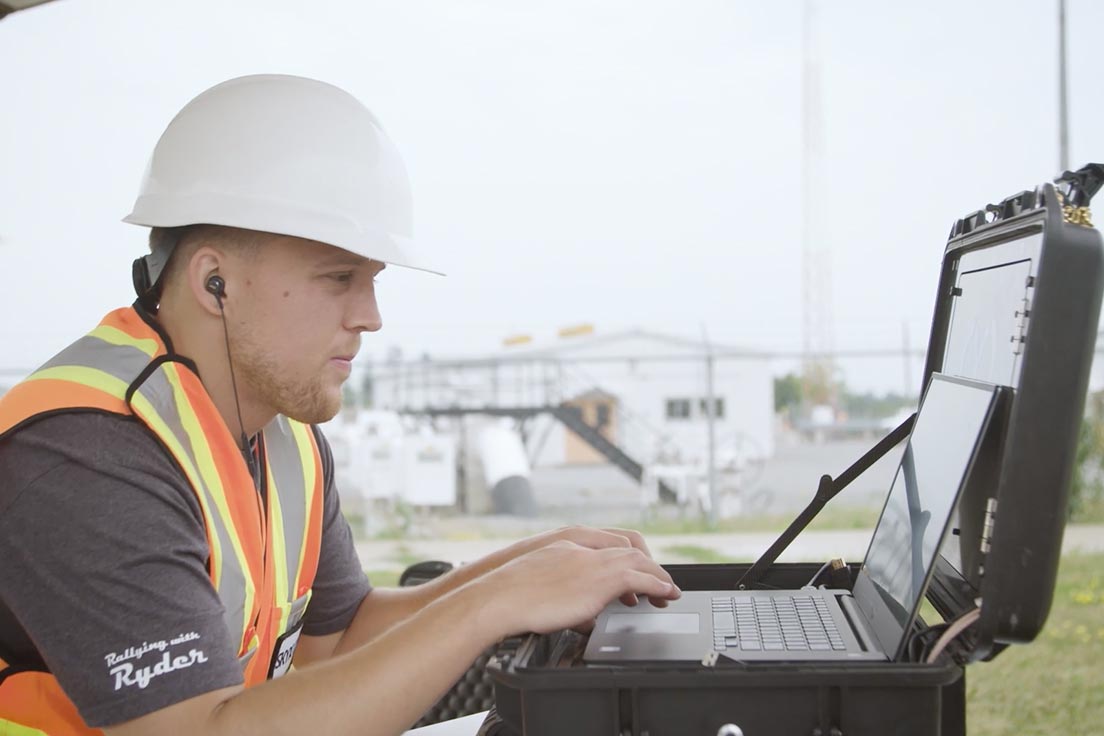

I head up our Flight Operations team, so depending on where SkyX is operating in the world, my team is responsible for the planning and execution of our data collection efforts in the field. This includes regulatory compliance, mission planning, site logistics, aerial system management, and of course – executing our flight operations in the field.

How do you approach a new pipeline monitoring project?

It all starts with developing a concept of operations. First and foremost is looking at the aviation regulations for where we’ll be operating, seeing how we comply, and what measures we need to take to prove airworthiness. A deployment approach is then determined, taking a phased approach from VLOS-to-BVLOS flights is required in most countries. Utilizing our VLOS operation as a means to demonstrate our operational and system capabilities to regulatory authorities and ultimately obtain a certificate or waiver to shift towards BVLOS operations.

The next step is is to conduct a site survey of the pipeline ROW, to determine potential hazards and best practices for the operation – so things like:

- Defining take-off and landing locations along the ROW

- Conducting a network survey to ensure optimal communications along the route

- Assessing the local weather conditions

- Completing an airspace assessment to determine potential conflicts with controlled airspace

- Identifying other hazards and obstacles that may interfere with the operation.

With that information, we put together a mission plan that maximizes our ability to perform long, automated mission flights – even in a VLOS scenario – and has both strategic and tactical measures in place to mitigate the risks we identified during the site evaluation.

Finally, we take all that planning we’ve done, go back to the site for a deployment visit, capture the data, and get it into the hands of our data analytics team to work their magic.

How do our midstream pipeline integrity services play out in the field? What are some of your considerations during flight?

Well, in the case of a VLOS operation where we’re doing a waypoint-navigated survey of a pipeline corridor: we’re flying from a series of take-off/landing points along the ROW, with a team of Visual Observers (VOs) deployed along each segment. These VOs are there to monitor the aerial system’s progress and report any potential flight conflicts. So, when we’re close to controlled airspace, I’m in close contact with local aviation authorities on air traffic activity, while the VO team watches closely for approaching aircraft.

There’s still potential for flight conflicts in uncontrolled airspace, and they don’t necessarily always come from other aircraft. On a recent monitoring project that involved flights over people with a lightweight sUAS, our system frequently caught the attention of hawks during flight, so our VO team was able to advise on avoidance maneuvers when necessary.

Wow, hawks? How do you deal with unexpected disturbances like that? Is it possible to plan for them?

Not necessarily, but this is a scenario where having a skilled team and clearly-outlined strategies in place make all the difference:

- Our VOs are placed so we always have a clear view of the drone and the surrounding area

- Our VOs know what to watch for and how to communicate potential conflicts to the Pilot-in-Command (PIC)

- And the PIC knows what measures to take to mitigate that conflict, whether it’s a descend, ascend, loiter, or controlled landing

So when one of these disturbances occurs – such as a hawk getting aggressive – the team handles it calmly and cooly, because we’re just working through our standard deconfliction process. I’m pleased to say no hawks have been harmed in the course of a SkyX right-of-way monitoring project!

UAV imagery is the foundation of the actionable data we provide to customers, how do we ensure we’re capturing the best imagery for the best resultant data?

This boils down to your sensor payload and the capture requirements for your desired data.

For our midstream pipeline integrity services, on the sensor-side, we usually use an HD RGB camera that can provide high-resolution visible-light images between 2 to 4 cm/pixel of ground sampling distance. Sometimes an operator may be looking for more specific visual intel – like thermal imaging with an infrared sensor – so that initiates a discovery process to hone in on what they specifically need from their UAV remote sensing program.

From there, we look at how we capture this imagery in a way that enables desired outputs and analytics. First, we consider what you are looking to achieve from these inspections in order to prescribe the appropriate flight cadence. Next, is what specific outputs you’re looking for. For instance, In the case of an orthomosaic, which really has become a must-have for pipeline operators, you want to make sure you’re capturing images with a high percentage of overlap during flight – to make sure you get a thorough model as the end result.

On orthomosaics, can you tell us about the digital models we can generate and how are these valuable to pipeline integrity managers?

Absolutely, I’m coming from a background in the geospatial world, so this is where a lot of the fun begins for me.

Orthomosaics have really become a standard delivery format in any inspection we do. They give you a comprehensive view of your pipeline ROW in a 2D plane.It provides an updated base layer of an asset, which can be viewed in a GIS application, and ultimately allows our clients to make educated decisions.

Another popular output is varying forms of Digital Elevation Models (DEMs) that operators can use to analyze key environmental factors along their ROW in a 3D space. For example, on many of our recent pipeline monitoring projects, we’re delivering Digital Terrain Models (DTMs) of the ROW that can be used to examine slope and pinpoint subtle changes in ground surface anomalies – which is essential to assembling a proactive maintenance plan. Plus, drones are really changing the quality and economics of generating these photogrammetric mapping models for the better.

And of course, these models grow all the more powerful when you have AI flagging the critical anomalies for your review.

Going from Data Collection to Data Analytics

Field operations, drone data collection, and digital model delivery is just the beginning of SkyX’s midstream pipeline integrity services. Next week, we’ll be exploring the data analytics side of things with Jason Braverman – Chief Technology Officer at SkyX – where you’ll learn:

- How SkyX leverages AI to refine drone imagery into actionable data

- The advantages of AI-driven computer vision systems in comparison to manual analysis

- How critical points of data are used to deliver predictive analytics

- How predictive analytics can help you in your day-to-day operations

Have questions about how high-quality aerial data can elevate your organization?

Contact our team to discuss your unique challenges and data requirements.